- Mani Casadona, Unit No : 2WS6C, Action Area-II F, New Town, Rajarhat, Kolkata-700156 INDIA

- +91-033-4814 6300

Product

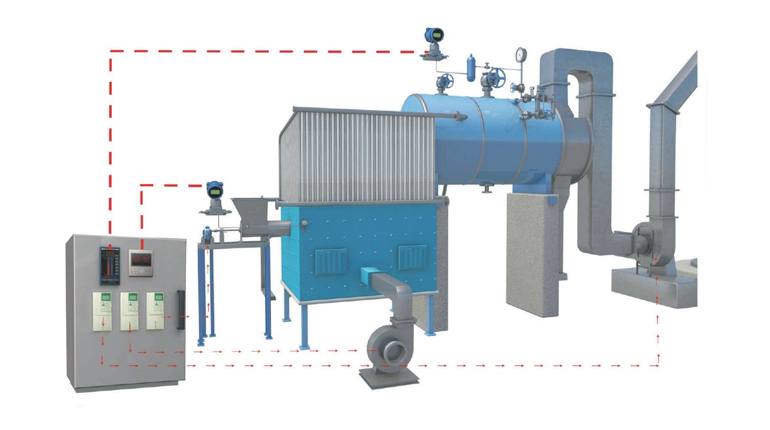

Draft Control System For Boiler ID Fan with Variable Frequency Drive (VFD)

Combustion Control System For Boiler With Variable Frequency Drive (VFD)

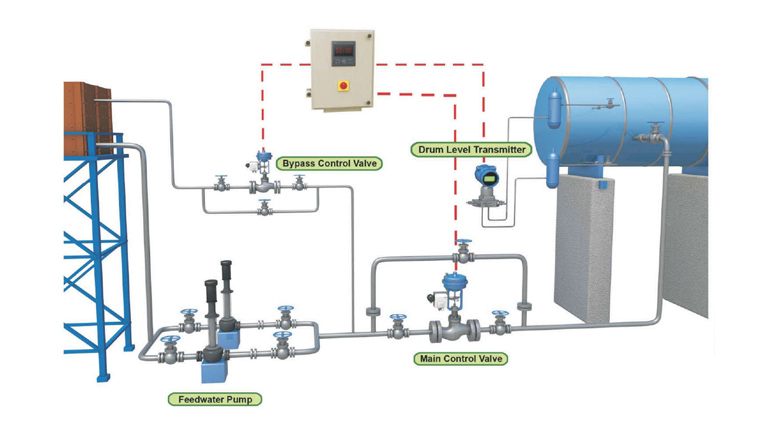

Single Element Control

The boiler drum is where water and steam are separated. Controlling its

level is critical if the level becomes too low, the boiler can run dry resulting in

mechanical damage of the drum and boiler piping. If the level becomes too high, water

can be carried over into the steam pipework, possibly damaging downstream equipment.

Boiler feedwater pump delivers water through control valve into the boiler drum. The water level in

the drum is measured with a level transmitter. The drum level controller drum level

controller compares the drum level measurement to the set level and regulates the main

feedwater control valve to keep the water level in the drum as per the set level.

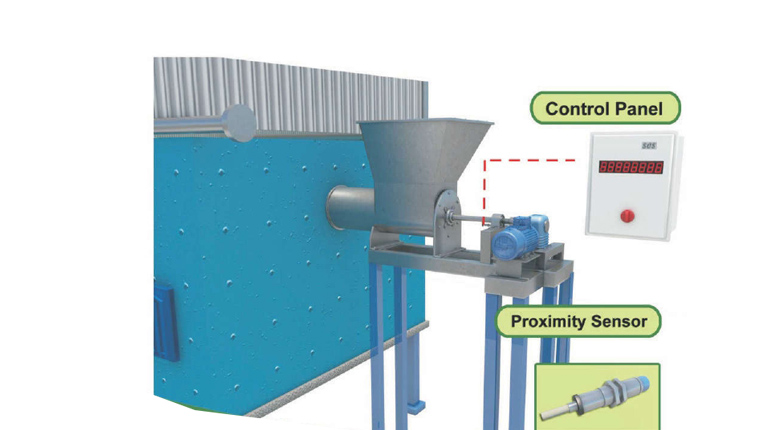

Fuel Measuring System

The system consists of a complete measuring device including a eight digit counter with a pre wired control panel. It gives day to day basis fuel consumption figure. It can be connected to DCS/PLC.

Automatic Blow Down System

TDS based automatic blowdown system ensures no scale deposition inside boiler due to TDS precipitation. The automatic valve fitted with boiler releases high TDS water from boiler to maintain desired TDS level to avoid precipitation or scaling inside boiler. Increases boiler up time and efficiency. Also tube or shell failure due to low heat transfer is avoided.