- Mani Casadona, Unit No : 2WS6C, Action Area-II F, New Town, Rajarhat, Kolkata-700156 INDIA

- +91-033-4814 6300

Product

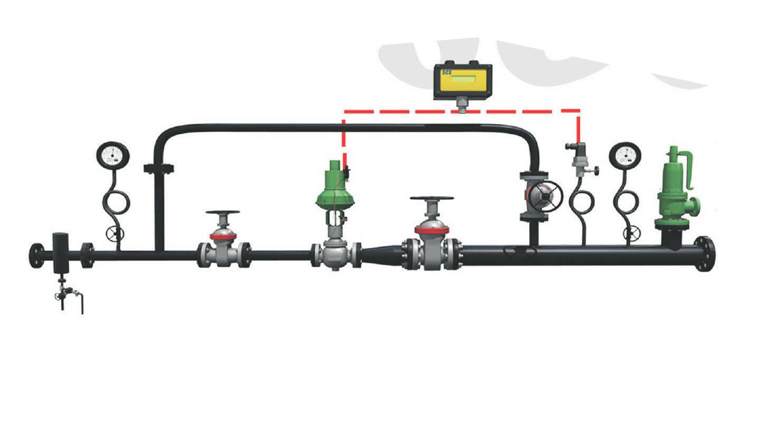

Pressure Reducing Station (PRS)

Features:

Suitable for both intermittent and continuous operation. Suitable for up to 25% inlet pressure variation. •Maintenance free and user friendly.

Application:

Pressure reduction for saturated & superheated steam and control by pilot operated spring loaded

pressure reducing valve and pneumatic control valve.

RANGE:

Capacity: 100 Kg/h to 15000 Kg/h and higher. Size: 15 to 300 NB and higher.

Desuperheating System (DSH)

PRDSH systems are designed to reduce the steam pressure to operating pressure. It also brings the outlet steam from superheated condition to saturated condition to improve heat transfer. The steam temperature is reduced close to saturation by injecting water into high velocity steam by controlled water flow through water control valve. Conventionally steam pressure reduction and temperature reduction were done in two different units. Now both these functions are carried in one unit which is a combined pressure reducing and desuperheating station.

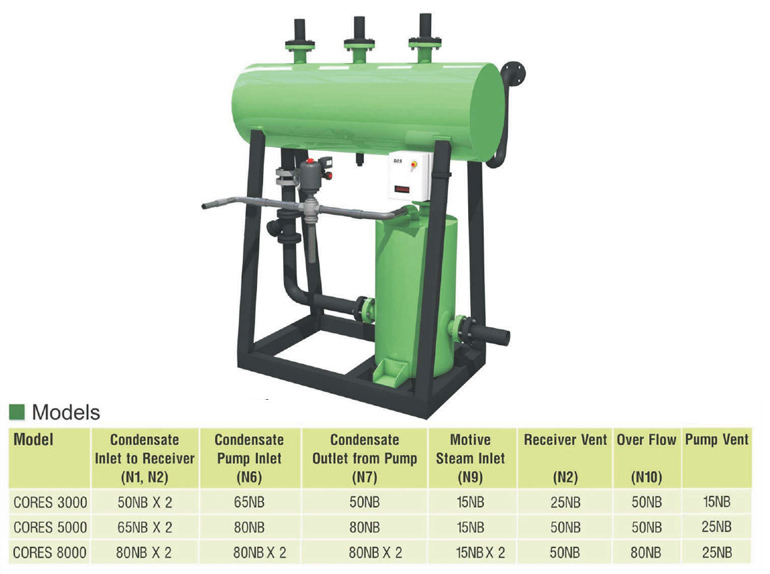

Condensate Recovery System

•Very reliable due to non moving parts. •Designed for high pressure. •High discharge capacity. •High temperature operation. •Skid mounted. •Zero maintenance.

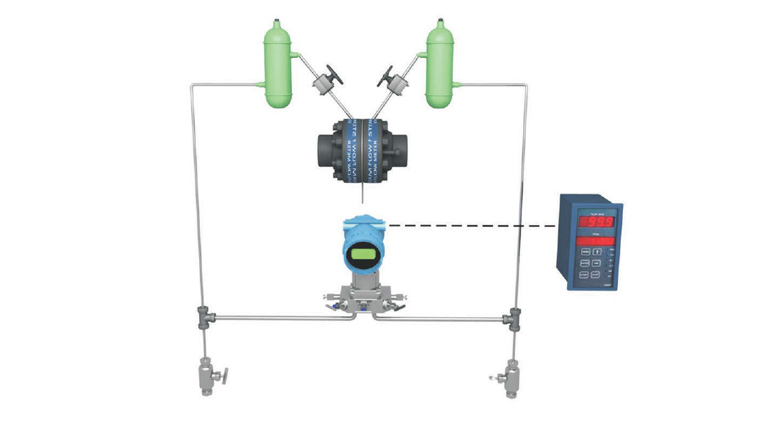

Steam Flow Meter

Steam Measurement Objective : Steam is generatated by combustion of expensive fuel in an industrial boiler. Its cost is an essential attribute to the manufacturing cost of product. So it is monitored on a continuous basis. Steam is measured to know the specific steam consumption & reduce the manufacturing cost.